-

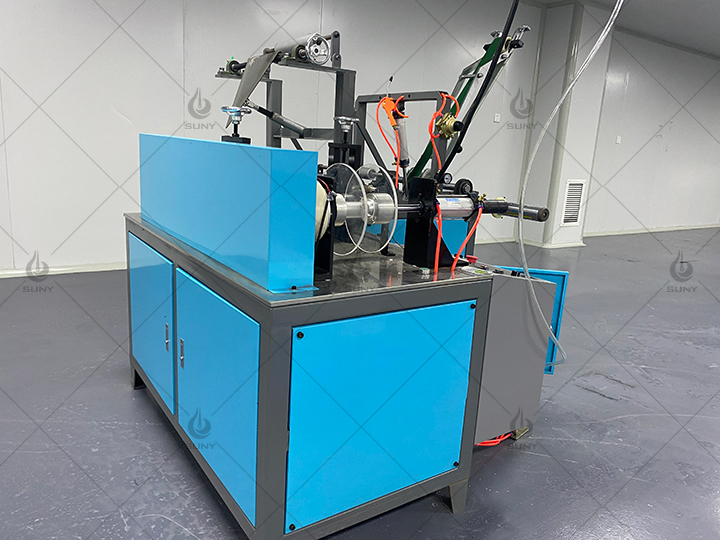

Handan Customer Chooses Cotton Soft Tissue Machine Production Line

- equipment: three-row cotton tissue machine,top-draw and bottom-draw packaging machine,towel roll heat sealer

country: china

capacity: 50 packs/minute

- CASE DETAILS

- INQUIRY

CASE DETAILSIn early 2025, a baby care product company in Handan began looking for a reliable cotton soft tissue machine production line to upgrade their production capacity and ensure high-quality output. During the initial stage, our sales and technical team conducted a comprehensive on-site inspection, understanding the workshop layout, production volume requirements, and specific product standards expected by the client.

Customer Requirements

The Handan customer emphasized several key points:

1.High-quality cotton tissue suitable for babies, soft and lint-free.

2.Fully automated production line to reduce labor costs and improve efficiency.

3.Stable, reliable machines capable of running 24/7 with minimal downtime.

4.Flexible packaging options to meet market needs.

Challenges Encountered

During the middle stage of the project, the team encountered several challenges:

1.Workshop space limitation – The available production area was smaller than standard layout requirements.

2.Production capacity adjustment – The client required a higher output than originally estimated.

3.Product softness consistency – Ensuring uniform softness for baby-grade tissue across large batches.

Solutions Implemented

To address these issues, our engineers customized the production line:

1.Redesigned the equipment layout to fit the limited workshop space without compromising workflow.

2.Upgraded the feeding and folding system to achieve the required production capacity of 120 rolls per minute.

3.Optimized the water-jet and air-laying system to maintain uniform fiber distribution, ensuring consistent softness.

4.Provided on-site training for the client’s operators to guarantee smooth operation and maintenance.

Results Achieved

After installation and commissioning, the Handan customer successfully achieved all goals:

1.Continuous, stable operation with high efficiency and minimal downtime.

2.Baby-grade cotton tissue produced met strict softness and quality standards.

3.The automated line significantly reduced labor costs and improved overall productivity.

4.Flexible packaging allowed the customer to quickly adapt to market demand.

This case demonstrates how a tailored cotton soft tissue machine production line can solve real-world production challenges. Through careful pre-sales assessment, customized engineering solutions, and professional support, the Handan customer realized their production goals while ensuring high-quality baby cotton tissues for the market.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related ProductQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. - equipment: three-row cotton tissue machine,top-draw and bottom-draw packaging machine,towel roll heat sealer