-

Handan customer upgrades cotton soft tissue machine production line

- equipment: three-row cotton towel machine,top-draw and bottom-draw packaging machine,towel roll heat sealer

country: china

capacity: 50 packs/minute

- CASE DETAILS

- INQUIRY

CASE DETAILSA customer in Handan aimed to upgrade their cotton towel production to meet the growing demand for high-quality cotton wipes in the mid-to-high-end market. They required a solution that could improve efficiency, ensure product consistency, and support sustainable production practices.

Challenges

1.Before the upgrade, the customer faced several challenges:

2.Low Production Efficiency: Traditional single-row machines could not meet market demand.

3.High Defect Rate: Manual processes led to uneven towel quality and frequent production errors.

4.Packaging Inefficiency: Existing packaging methods were slow and often caused damaged products.

5.Limited Automation: Lack of smart controls resulted in high labor costs and frequent downtime.

Solution

To address these issues, the customer chose a complete production line solution:

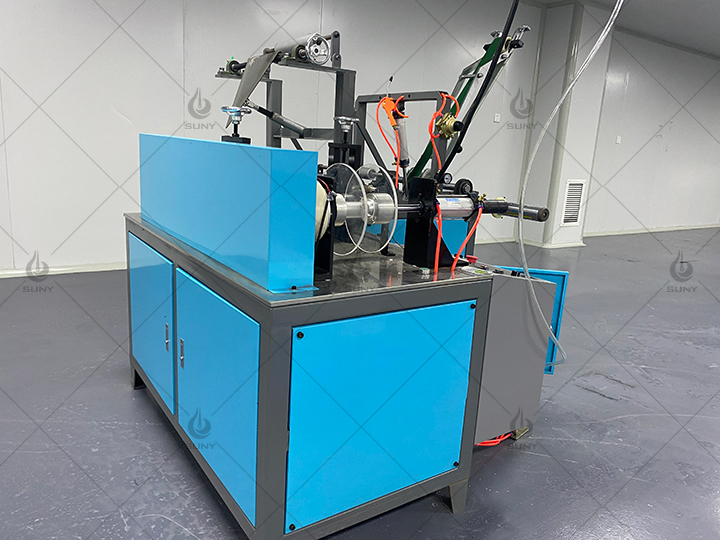

Three-Row Cotton Towel Machine – Features a servo control system and hydroentanglement technology for uniform fiber distribution, producing soft and strong towels at 80–100 meters per minute. The machine also includes automatic yarn breakage detection to reduce defects.

Top-Draw and Bottom-Draw Packaging Machine – Integrates counting, stacking, and bagging functions. Food-grade stainless steel construction meets GMP standards, and the draw-out design prevents continuous draw errors.

Towel Roll Heat Sealer – Uses constant-temperature heat-pressure sealing technology to ensure airtight packaging with real-time visual inspection to reject defective products.

The entire line is modular, PLC-controlled, and includes an IoT interface for remote monitoring and data analysis, enabling quick production changeovers and smart factory integration.

Results

After implementing the solution:

1.Production efficiency increased significantly, meeting high market demand.

2.Defective product rates dropped, ensuring uniform quality.

3.Energy consumption reduced by 30%, and labor costs decreased by 60%.

4.Flexible production for towel sizes 20×20cm to 25×25cm with multiple raw materials.

5.Enhanced competitiveness in the high-end cotton wipe market.

The Handan customer successfully upgraded their facility, achieving higher efficiency, consistent quality, and faster return on investment. This case demonstrates how combining advanced cotton towel machinery, automated packaging, and reliable heat sealing can solve production challenges and support business growth.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related ProductQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved.- Inquiry

- Top

- equipment: three-row cotton towel machine,top-draw and bottom-draw packaging machine,towel roll heat sealer