-

Linyi Customer Upgrades Cotton Tissue Production

- equipment: a three-row cotton tissue machine,a top-draw packaging machine

country: china

capacity: 30 packs/minute

- CASE DETAILS

- INQUIRY

CASE DETAILSA customer in Linyi sought to enhance their cotton tissue production line to meet increasing demand for high-quality towels in the domestic and export markets. The goal was to improve production efficiency, reduce defects, and streamline packaging operations.

Challenges

Before upgrading, the customer faced several challenges:

1.Limited Production Capacity: Single-row machines could not meet growing market demand.

2.Inconsistent Product Quality: Manual handling and older machines resulted in uneven towel thickness and occasional defects.

3.Inefficient Packaging: Traditional packaging methods slowed the overall production process.

Solution

Sunny Industry provided a complete solution, including:

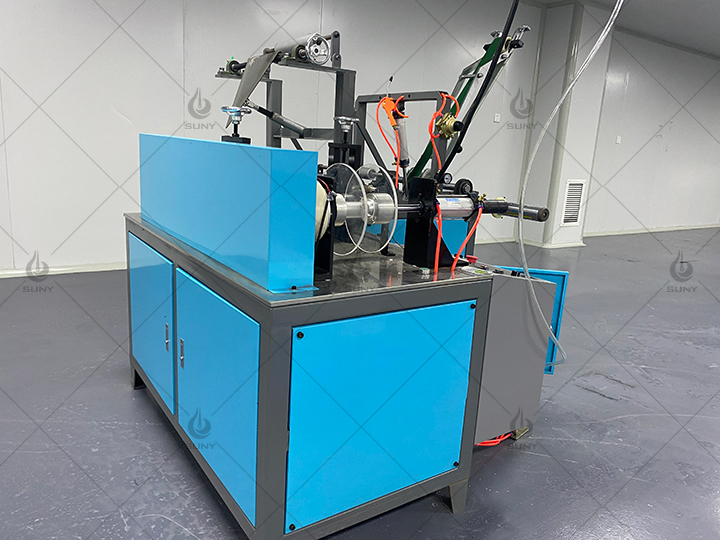

1.Three-Row Cotton Tissue Machine – Equipped with servo control and advanced hydroentanglement technology, ensuring uniform fiber distribution and soft, strong towels. The machine increases output while reducing defective products.

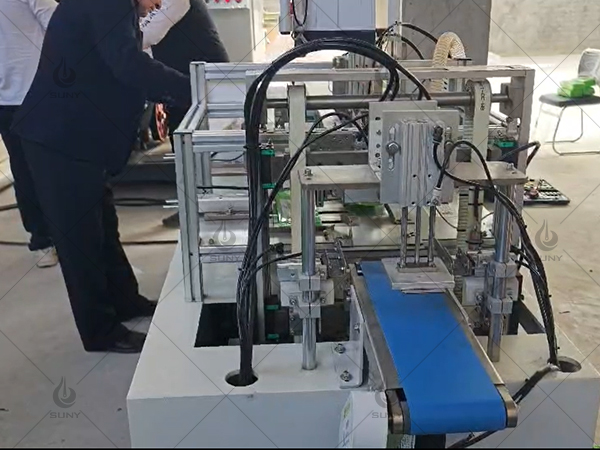

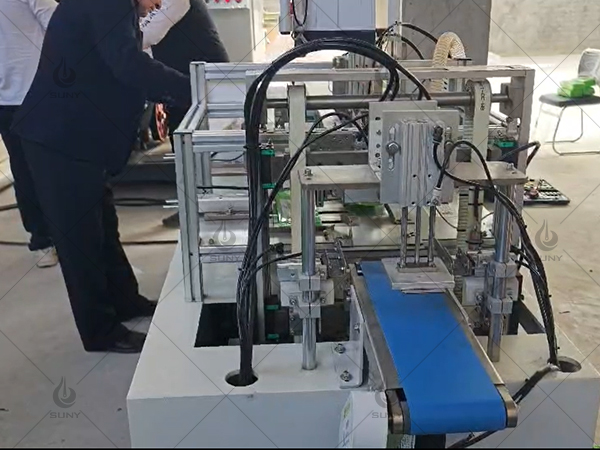

2.Top-Draw Packaging Machine – Integrates automatic counting, stacking, and bagging functions. Its design improves workflow efficiency, reduces labor, and maintains hygiene standards.

The solution is modular and PLC-controlled, allowing smooth operations and easy adjustments for different towel sizes and materials.

Results

After implementation:

1.Production efficiency significantly improved, meeting market demand.

2.Defective product rates reduced, ensuring consistent towel quality.

3.Packaging efficiency increased, saving time and labor.

4.Flexible production for various tissue sizes and raw materials.

This project demonstrates how combining advanced three-row cotton tissue machines with automated top-draw packaging solutions can solve production challenges and help customers achieve faster ROI while maintaining high-quality standards.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related ProductQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. - equipment: a three-row cotton tissue machine,a top-draw packaging machine