-

China Pingdingshan customers purchase three-row cotton wipes + pre-made bag top-draw packaging machine

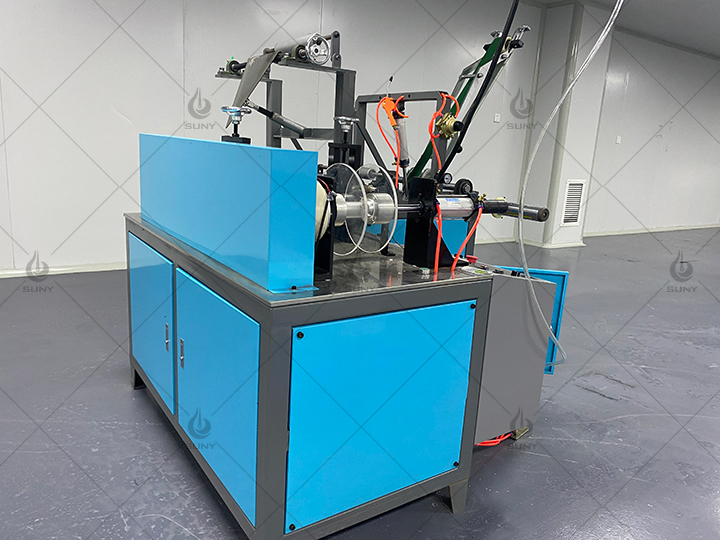

- equipment: three-row cotton wipes,pre-made bag top-draw packaging machine

country: china

capacity: 50-70 packs/minute

- CASE DETAILS

- INQUIRY

CASE DETAILSRecently, a customer in Pingdingshan, China, reached a strategic cooperation agreement with Sunny Industrial, successfully introducing a three-row cotton wipe production line integrated with a pre-made bag top-loading automatic packaging machine. This collaboration represents a significant step forward in intelligent production, marking a major upgrade in the customer’s manufacturing capacity and operational efficiency.

1.Advanced Technical Integration

The equipment provided by Sunny Industrial demonstrates exceptional technical integration:

Three-Row Cotton Wipe Machine: Features a modular design with a precision hydroentanglement forming system and an intelligent temperature-controlled drying unit, capable of producing three rows of cotton wipes simultaneously at up to 120 meters per minute.

Pre-Made Bag Top-Loading Packaging Machine: Fully automates the process from bag making to filling, using a vision positioning system for precise bag filling at speeds of up to 60 bags per minute.

The entire line leverages Industrial Internet technology, enabling real-time production monitoring and remote operation and maintenance through a central control system.

2.Key Benefits

This intelligent production line delivers multiple advantages to the Pingdingshan customer:

Increased Production Capacity: The three-row design triples daily output compared to traditional single-row equipment, effectively meeting growing market demand.

Enhanced Product Quality: Pre-made bag packaging improves product aesthetics, strengthens seals, and ensures hygiene and consistency.

Reduced Labor Costs: Automated packaging minimizes manual intervention, lowering production costs while maintaining consistent product quality.

3.On-site Problem and Solution for a Three-Row Cotton Towel Machine

During production, the middle row of a three-row cotton towel machine experienced uneven feeding, resulting in incorrect stacking. The operator immediately stopped the machine, recalibrated the middle row feed rollers, and adjusted the cotton roll tension. After a low-speed test run, feeding and stacking returned to normal. With the dedicated assistance of our engineers, the problem was resolved within 15 minutes, minimizing downtime and ensuring consistent cotton towel quality. The operator also informed the customer of the solution and the potential problems that could occur, and they were very satisfied.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related ProductQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. - equipment: three-row cotton wipes,pre-made bag top-draw packaging machine