-

NewsPosition :Home >

- News> Industry news > Baby Cotton Tissue Machine with Embossing System

Baby Cotton Tissue Machine with Embossing System

2025-12-01 15:48:49Baby Cotton Tissue Machine with Embossing System is a professional hygiene-product manufacturing solution designed to produce ultra-soft, lint-free cotton tissues used in infant care. As baby care products increasingly shift toward natural and chemical-free materials, manufacturers require advanced machinery that supports high-precision production, consistent quality, and efficient output. This machine integrates cutting, embossing, folding, and packaging operations, delivering a full automated line suitable for both small and large-scale production plants.

The structure and workflow of the machine follow a systematic process to ensure stability and precision. The typical operational sequence includes:

-

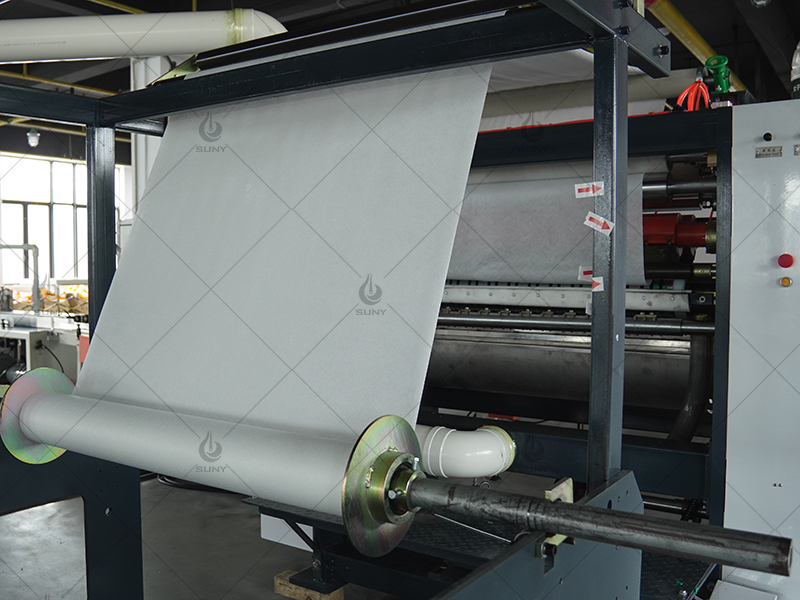

Raw Material Unwinding – Non-woven cotton rolls are fed into the machine using tension-controlled unwinding units.

-

Embossing Stage – Materials pass through steel-and-rubber or steel-and-steel embossing rollers to form patterns.

-

Automatic Folding – Servo-driven folding systems create uniform Z-fold or multi-fold formats.

-

Length Cutting – High-speed cutters trim the tissues into accurate sizes.

-

Counting and Stacking – Optical sensors ensure precise sheet counting and stacking.

-

Packaging Output – Finished tissues are conveyed to the packaging area for sealing or bagging.

This embossing system serves as a key differentiating feature and provides functional and aesthetic advantages. Embossing patterns reinforce material structure, making the tissues stronger while maintaining softness. The textured surface improves absorption, which is especially important for cleaning baby skin. Manufacturers can choose from multiple pattern options, such as:

-

Honeycomb patterns

-

Floral patterns

-

Dot textures

-

Wave patterns

-

Customized brand-logo embossing

These pattern selections enhance product appearance, support brand recognition, and improve overall tactile feel.

The machine delivers strong production efficiency supported by advanced automation. PLC control, touchscreen interfaces, and automatic fault detection help reduce human error and increase stability. With adjustable production speed, servo motors, and precise alignment systems, manufacturers can achieve high capacity while maintaining strict quality requirements. Additional sensors monitor tension, material position, and cutting accuracy, ensuring that every pack of cotton tissue meets hygiene and dimensional standards.

For baby care product manufacturers, the machine provides several key benefits:

-

Consistent Output Quality – Ensures gentle, uniform tissues suitable for newborn skin.

-

Cost-Effective Production – Reduces labor and material waste through automated processes.

-

Flexible Product Customization – Supports multiple sizes, fabric weights, and embossing designs.

-

Regulatory Compliance – Meets hygiene production standards required for infant-care goods.

-

Brand Differentiation – Embossed patterns and premium finishing improve market competitiveness.

The global market demand for baby cotton tissues continues to grow as parents seek safe, disposable, and fragrance-free cleaning solutions. These tissues serve multiple uses, including face cleaning, feeding care, bath routines, diaper changes, and household hygiene. They are widely adopted by hospitals, maternity centers, and childcare institutions. The combination of softness, durability, and chemical-free material makes cotton tissues a preferred alternative to wet wipes and traditional paper tissues.

Previous Page:Next Page:Quick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. -