-

NewsPosition :Home >

- News> Industry news > Wet and Dry Cotton Tissue Machine Production Line

Wet and Dry Cotton Tissue Machine Production Line

2025-10-31 16:21:00With the growing demand for hygiene, skincare, and eco-friendly products, the wet and dry cotton tissue machine production line has become a popular choice for modern manufacturers. This production system efficiently produces both dry and wet cotton tissues, which are widely used in households, hospitals, beauty salons, and baby care industries. Combining automation, versatility, and high production efficiency, it enables businesses to meet diverse market needs with one integrated solution.

Uses of Wet and Dry Cotton Tissues

Wet and dry cotton tissues serve multiple purposes across various industries. Dry cotton tissues are commonly used for facial cleaning, makeup removal, and baby care. When soaked in water, they instantly become soft wet wipes, offering a more hygienic alternative to traditional paper tissues. Wet cotton tissues, on the other hand, are pre-moistened with purified water or natural lotion, making them suitable for gentle skincare, travel hygiene, and daily cleaning. Both types are made from 100% cotton fiber, ensuring softness, strength, and biodegradability.

Introduction to the Wet and Dry Cotton Tissue Machine

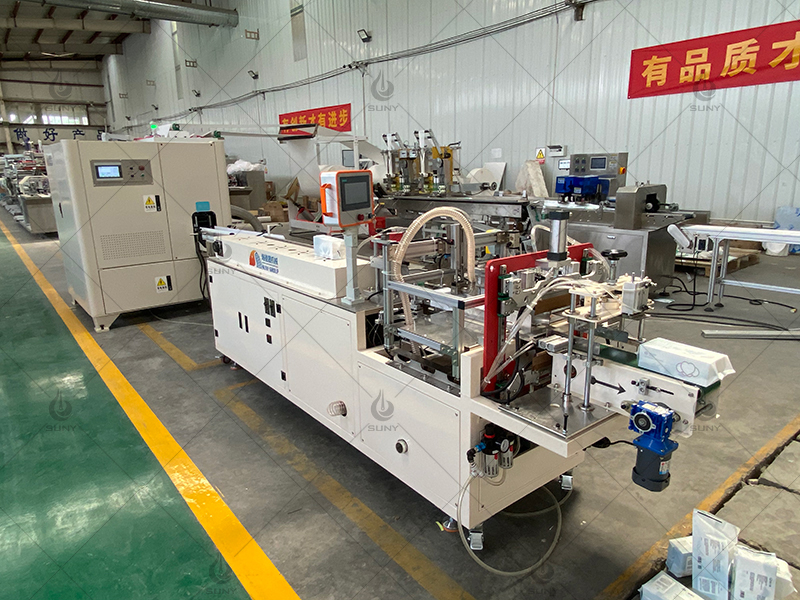

The wet and dry cotton tissue machine is a fully automated system that integrates cotton fiber feeding, web forming, cutting, folding, wetting (optional), and packaging. It can switch easily between dry and wet production modes depending on product requirements. The machine adopts advanced servo control and PLC automation to ensure stable operation and precise cutting dimensions. Its compact structure, energy-saving design, and high-speed output make it suitable for both small-scale startups and large production factories.

Configuration of the Production Line

A complete wet and dry cotton tissue machine production line typically includes the following units:

-

Cotton fiber feeding and web forming system – Converts natural cotton into a uniform web.

-

Embossing and cutting unit – Shapes and sizes tissues according to design.

-

Folding and stacking machine – Ensures accurate folding and neat stacking for packaging.

-

Wetting and liquid filling section – For producing wet tissues with purified water or additives.

-

Packaging unit – Automatically seals tissues in rolls, boxes, or individual sachets.

-

Control system – PLC and touch screen operation for easy parameter adjustments.

This configuration ensures continuous production with minimal labor input and high consistency in product quality.

Features of Wet and Dry Cotton Tissues

-

100% natural cotton: Soft, absorbent, and skin-friendly without chemical additives.

-

Dual-purpose use: Can be used dry or turned into a wet wipe with a small amount of water.

-

Strong and lint-free: Durable enough for both cleaning and skincare applications.

-

Eco-friendly: Biodegradable and non-polluting, supporting sustainable consumption.

-

Hygienic and safe: Produced in dust-free environments to meet medical and cosmetic standards.

The wet and dry cotton tissue machine production line represents the future of modern tissue manufacturing. It combines advanced automation with flexible production capabilities, allowing manufacturers to supply high-quality cotton tissues for diverse consumer needs. With increasing global awareness of hygiene and sustainability, investing in such a production line not only ensures business growth but also supports environmentally responsible manufacturing.

Previous Page:Quick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. -