-

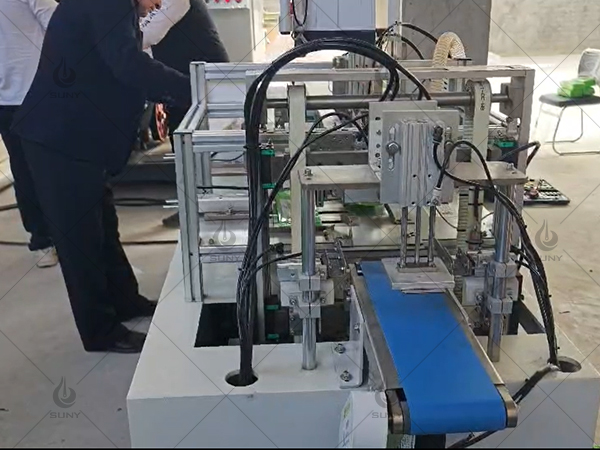

8 Lanes Fully-Automatic Bottom Extraction Cotton Tissue Machines

- model: 8 Lanes Fully-Automatic Bottom Extraction Cotton Tissue Machines

capacity: 80-120 m/min

Max Width of Fabric: 1620 mm

- INTRODUCTION

- SPECIFICATION

- VIDEO

- INQUIRY

INTRODUCTIONProduct Introduction

The 8 Lanes Fully-Automatic Bottom Extraction Cotton Tissue Machines from Sunny Industry are designed for high-capacity cotton Tissue production. Using an advanced bottom extraction system, these machines provide smooth, jam-free Tissue dispensing while maintaining uniform fiber distribution. Ideal for modern textile factories, they offer consistent quality, high-speed operation, and automation for mid-to-high-end cotton Tissue manufacturing.

Key Features

1.Eight-Lane High-Capacity Production – Supports simultaneous production across eight lanes, maximizing output.

2.Bottom Extraction Mechanism – Utilizes gravity-assisted dispensing to prevent paper jams and reduce waste.

3.Servo-Controlled Automation – Ensures precise fiber tension, folding, and cutting for uniform Tissue quality.

4.Energy-Efficient Operation – Optimized design reduces electricity and water consumption while maintaining high speed.

5Intelligent Monitoring & Control – PLC system with touch-screen interface allows real-time monitoring and easy adjustments.Suitable Materials

These machines are compatible with various cotton-based materials, including:

-Pure cotton fibers

-Cotton-blend fabrics

-Nonwoven cotton wipes

-Eco-friendly recycled cotton materialsFinal Products

The 8 Lanes Fully-Automatic Bottom Extraction Cotton Tissue Machines produce:

Facial cotton Tissues

-Baby wipes

-Household cotton Tissues

-Spa and cosmetic wipesAll products feature uniform thickness, soft texture, high tensile strength, and hygiene standards suitable for mid-to-high-end markets.

SPECIFICATIONEquipment Name 8 Lanes Cotton towel Folding Machine Max Width of Fabric 1620 mm Max Diameter of Fabric 1500 mm Folding Method V-type Production Speed 80-120 m/min Power Supply 380V 50Hz Power 37 kW Dimensions(L*W*H) 6800*2800*2100 mm Machine Weight 4800 kg Extraction Method BOTTOM VIDEO InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. - model: 8 Lanes Fully-Automatic Bottom Extraction Cotton Tissue Machines