-

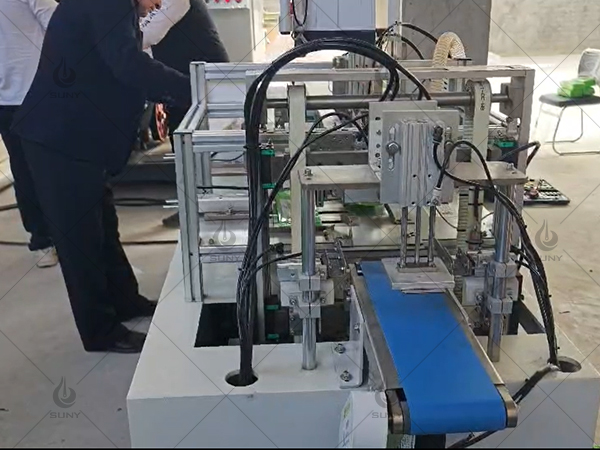

8 Lanes Fully-Automatic Top Extraction Cotton Tissue Machines

- model: 8 Lanes Fully-Automatic Top Extraction Cotton Tissue Machines

capacity: 80-120 m/min

Max Width of Fabric: 1620 mm

- INTRODUCTION

- SPECIFICATION

- VIDEO

- INQUIRY

INTRODUCTIONProduct Introduction

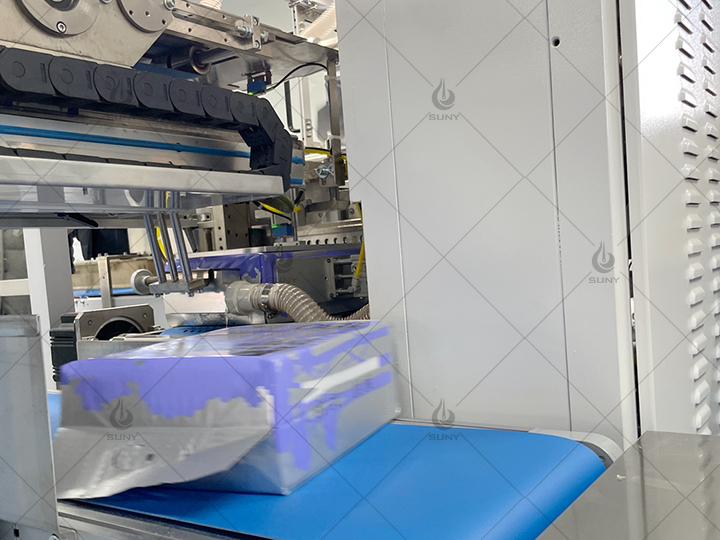

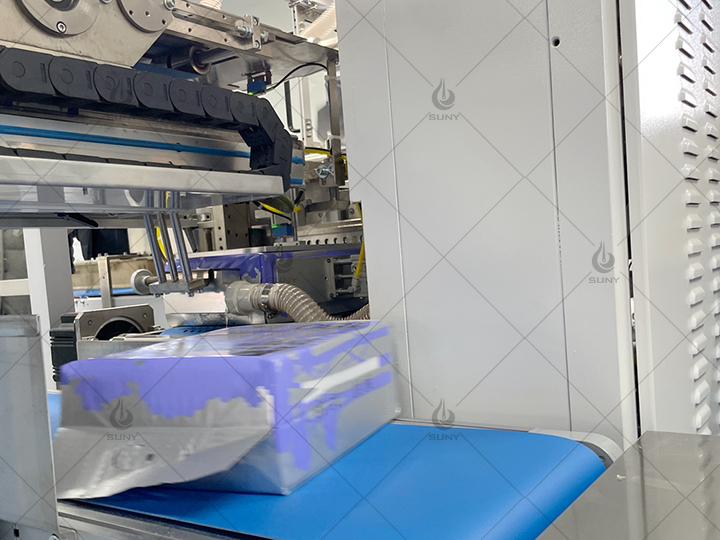

The SUNY 8-Step Automatic Top-Draw Cotton Tissue Machine is a high-efficiency solution designed for modern cotton tissue production. Combining advanced automation and intelligent control, it streamlines the entire manufacturing process from feeding to folding. The machine is engineered to deliver uniform, soft, and strong cotton tissues, ideal for mid-to-high-end personal care and household products.

Key Features

1.Eight-Step Automated Process – Integrates feeding, hydroentanglement, drying, folding, cutting, stacking, and counting in one seamless workflow.

2.Servo-Controlled Operation – Provides precise speed and tension control for consistent product quality.

3.Energy-Efficient Design – Reduces electricity and water consumption compared to traditional machines.

4.User-Friendly Interface – Touch-screen control and PLC system enable easy operation and real-time monitoring.

5.High Reliability – Durable components and automatic error detection minimize downtime and maintenance costs.

Suitable Materials

The machine is compatible with a wide range of raw materials, including:

1.Pure cotton fibers

2.Cotton-blend fabrics

3.Nonwoven cotton wipes

4.Eco-friendly recycled cotton materials

Final Products

The SUNY 8-Step Automatic Top-Draw Cotton Tissue Machine produces:

-Facial tissues

-Baby tissues

-Household cotton tissues

-Spa and cosmetic tissues

Its output features uniform thickness, soft texture, and high strength, meeting the quality standards of mid-to-high-end markets.

SPECIFICATIONEquipment Name 8 Lanes Cotton Tissue Machine Max Width of Fabric 1620 mm Max Diameter of Fabric 1500 mm Folding Method V-type Production Speed 80-120 m/min Power Supply 380V 50Hz Power 37 kW Dimensions(L*W*H) 6800*2800*2100 mm Machine Weight 4800 kg Extraction Method TOP VIDEO InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. - model: 8 Lanes Fully-Automatic Top Extraction Cotton Tissue Machines