-

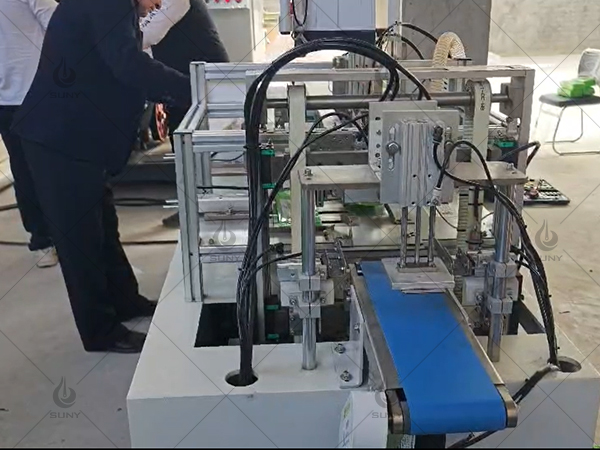

5 Lanes Semi-Automatic Top Extraction Cotton Tissue Machines

- model: 5 Lanes Semi-Automatic Top Extraction Cotton Tissue Machines

capacity: 80-100 m/min

Max Width of Fabric: 1050 mm

- INTRODUCTION

- SPECIFICATION

- VIDEO

- INQUIRY

INTRODUCTIONThe 5 Lanes Semi-Automatic Top Extraction Cotton Tissue Machine is designed to deliver high-quality tissue production while maintaining operational flexibility and efficiency. Ideal for medium-scale manufacturing, this machine combines semi-automation with a multi-lane design, ensuring consistent output and reduced labor requirements.

Equipment Workflow

The production process is structured to ensure smooth operations:

1.Material Loading – Rolls of cotton or nonwoven fabric are fed into the machine.

2.Sheet Cutting – The material is precisely cut into required dimensions for top-extraction tissues.

3.Folding and Layering – Sheets are folded and stacked into neat layers for uniform packing.

4.Counting and Packing – Semi-automatic counters track sheet quantity, and operators complete final packing efficiently.

This workflow enables stable production while minimizing human errors and material wastage.

Features and Advantages

1.Five-Lane Operation – Increases production capacity without increasing footprint.

2.Semi-Automatic System – Balances automation and manual control for flexibility.

3.Robust Construction – Heavy-duty frames and precision components ensure durability and long service life.

4.Energy Efficient – Optimized power usage reduces operating costs.

5.Simple Operation – User-friendly controls and maintenance accessibility streamline daily tasks.

Competitive Edge

The machine offers advantages that strengthen manufacturers’ market position:

1.High Throughput – Five parallel lanes allow simultaneous processing of multiple sheets.

2.Cost-Efficient – Lower investment compared to fully automatic lines while maintaining high output.

3.Versatile Production – Supports different tissue sizes and packaging styles for diverse market needs.

4.Consistent Quality – Accurate folding and stacking result in premium, uniform products.

Final Product Attributes

Tissues produced by this machine are:

1.Soft and Gentle – Made from high-grade cotton or nonwoven materials, suitable for skin contact.

2.Top-Pull Convenience – Easy-to-use top extraction design enhances user experience.

3.Uniform and Neat – Precision folding ensures aesthetically pleasing packs.

4.Environmentally Friendly – Biodegradable materials align with sustainable consumption trends.

The 5 Lanes Semi-Automatic Top Extraction Cotton Tissue Machine provides manufacturers with a practical, efficient solution for producing high-quality tissues. Its combination of multi-lane design, semi-automation, and reliable output ensures competitive advantage in a growing and demanding market.

SPECIFICATIONEquipment Name 5 Lanes Cotton tissue Folding Machine Max Width of Fabric 1050 mm Max Diameter of Fabric 1500 mm Folding Method V-type Production Speed 80-100 m/min Power Supply 380V 50Hz Power 18.5 kW Dimensions(L*W*H) 6800*2200*2100mm Machine Weight 4000 kg Extraction Method TOP VIDEO InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. - model: 5 Lanes Semi-Automatic Top Extraction Cotton Tissue Machines