-

Cotton tissue folding machine

- model: Cotton tissue folding machine

capacity: 60-100 m/min

Max Width of Fabric: 1620 mm

- INTRODUCTION

- SPECIFICATION

- VIDEO

- INQUIRY

INTRODUCTIONProduct Introduction

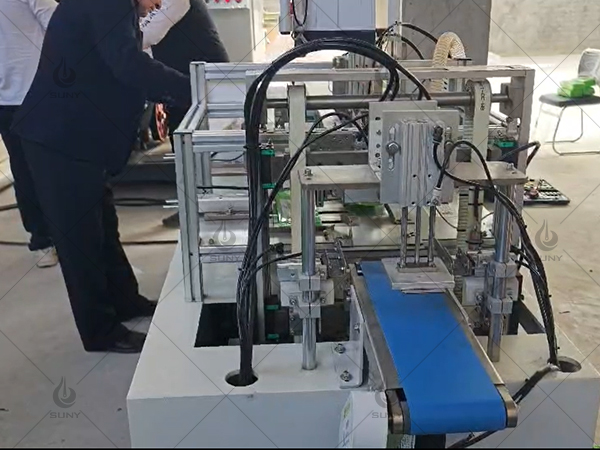

The cotton tissue folding machine is a key piece of equipment in the nonwoven industry, designed to fold, cut, and shape cotton-based fabric into consumer-ready tissues. With the rising global demand for soft, eco-friendly, and skin-safe cotton tissues, this machine plays a vital role in ensuring efficient production and consistent product quality. Its advanced automation, flexible design, and precision control make it an indispensable solution for manufacturers seeking to expand in the hygiene market.

Introduction to Cotton Tissue Folding Machine

A cotton tissue folding machine is specialized in processing nonwoven cotton fabric into folded tissues of various sizes and formats. Unlike traditional tissue machines, it is designed specifically for pure cotton or cotton-blend materials, ensuring softness, absorbency, and durability. It is widely used in the production of dry cotton tissues, makeup remover tissues, baby care tissues, and household cleaning wipes.

How the Cotton Tissue Folding Machine Works

The working process begins with raw cotton nonwoven rolls. The fabric is unwound and fed into the machine, where it undergoes cutting, folding, and stacking. Advanced folding systems allow for precise and uniform shaping, whether in Z-fold, N-fold, or customized folding patterns. Once folded, the tissues are stacked into bundles and sent for packaging. Some machines integrate automatic counting, embossing, or perforation functions, ensuring both efficiency and versatility in the production line.

Key Considerations When Choosing a Cotton Tissue Folding Machine

Selecting the right cotton tissue folding machine is crucial for stable production and long-term business success. Manufacturers should consider the following factors:

-

Production Capacity – Choose a machine that matches expected output, whether for small-scale workshops or large factories.

-

Automation Level – Fully automatic systems reduce labor costs and minimize errors compared to semi-automatic models.

-

Folding Options – Ensure the machine supports multiple folding styles to meet different market demands.

-

Maintenance and Durability – High-quality components and easy-to-replace parts extend machine lifespan and reduce downtime.

-

Energy Efficiency – Modern machines integrate low-power systems, lowering operational costs while maintaining stable output.

Applicable Raw Materials

The cotton tissue folding machine is suitable for various types of raw materials, primarily:

-

100% Cotton Nonwoven Fabric – Offers premium softness and skin-friendly qualities.

-

Cotton-Blend Nonwovens – A cost-effective option with balanced durability.

-

Biodegradable Nonwoven Fabrics – Eco-friendly materials that align with global sustainability trends.

These flexible material options enable manufacturers to produce a wide range of tissue products catering to diverse consumer preferences.

Conclusion

The cotton tissue folding machine is more than just equipment—it is a technological investment for businesses entering or expanding in the cotton tissue market. By ensuring precise folding, consistent product quality, and efficient output, this machine helps meet the growing demand for natural and sustainable hygiene products. For manufacturers aiming at long-term competitiveness, choosing the right folding machine is a crucial step toward success.

SPECIFICATIONEquipment Name 8-row cotton towel folding machine 5-row cotton towel folding machine 3-row cotton towel folding machine Maximum width of original fabric 1620 mm 1050 mm 650 mm Maximum diameter of original fabric 1500 mm 1500 mm Folding method V-type Production speed 80-100 m/min 90-100 m/min 60-100 m/min Quantitative sampling 30-500 draws Power supply type 380V 50Hz Fan power 37 kW 18.5 kW 15 kW Overall dimensions (length, width, height) L6000mm*W2800mm*H2300mm L2500mm*W2190mm*H2338mm Machine weight 5000 kg VIDEO InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved.

InquiryIf you would like to contact us for more information about our products ,please fill out the form below,thank you.Related CaseQuick consultationZhengzhou SUNY Industrial Co., Ltd. , a SUNY Group subsidiary, specializes in manufacturing sanitary equipment including wet wipes machines, mask machines and diaper production lines. Headquartered in Zhengzhou, it integrates R&D, production and sales with China's leading sanitary automation expertise.ProductsCopyright: 2011-2025 Zhengzhou SUNY Industrial Co., Ltd. All rights reserved. - model: Cotton tissue folding machine